Our Services

Comprehensive solutions for all your industrial needs

Engineering Solutions

Comprehensive engineering services tailored to your specific industrial requirements and challenges.

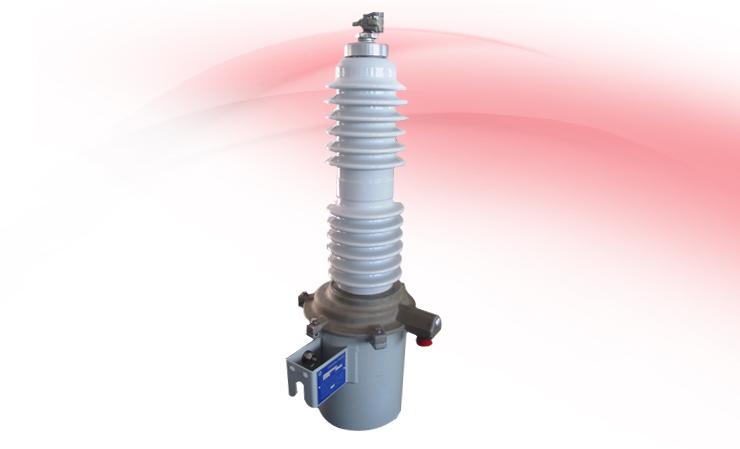

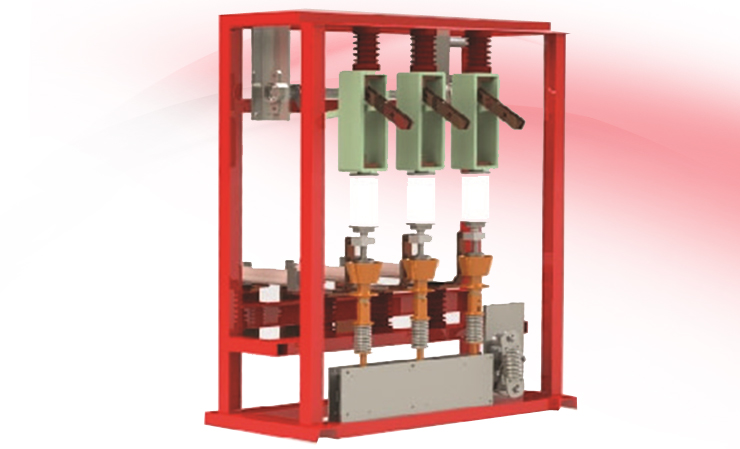

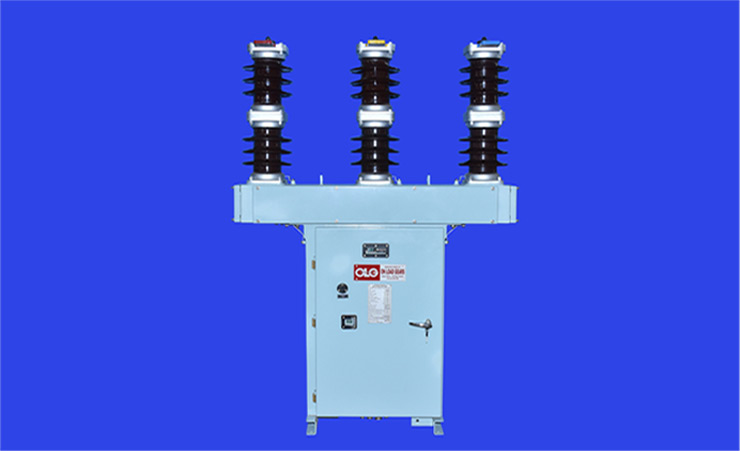

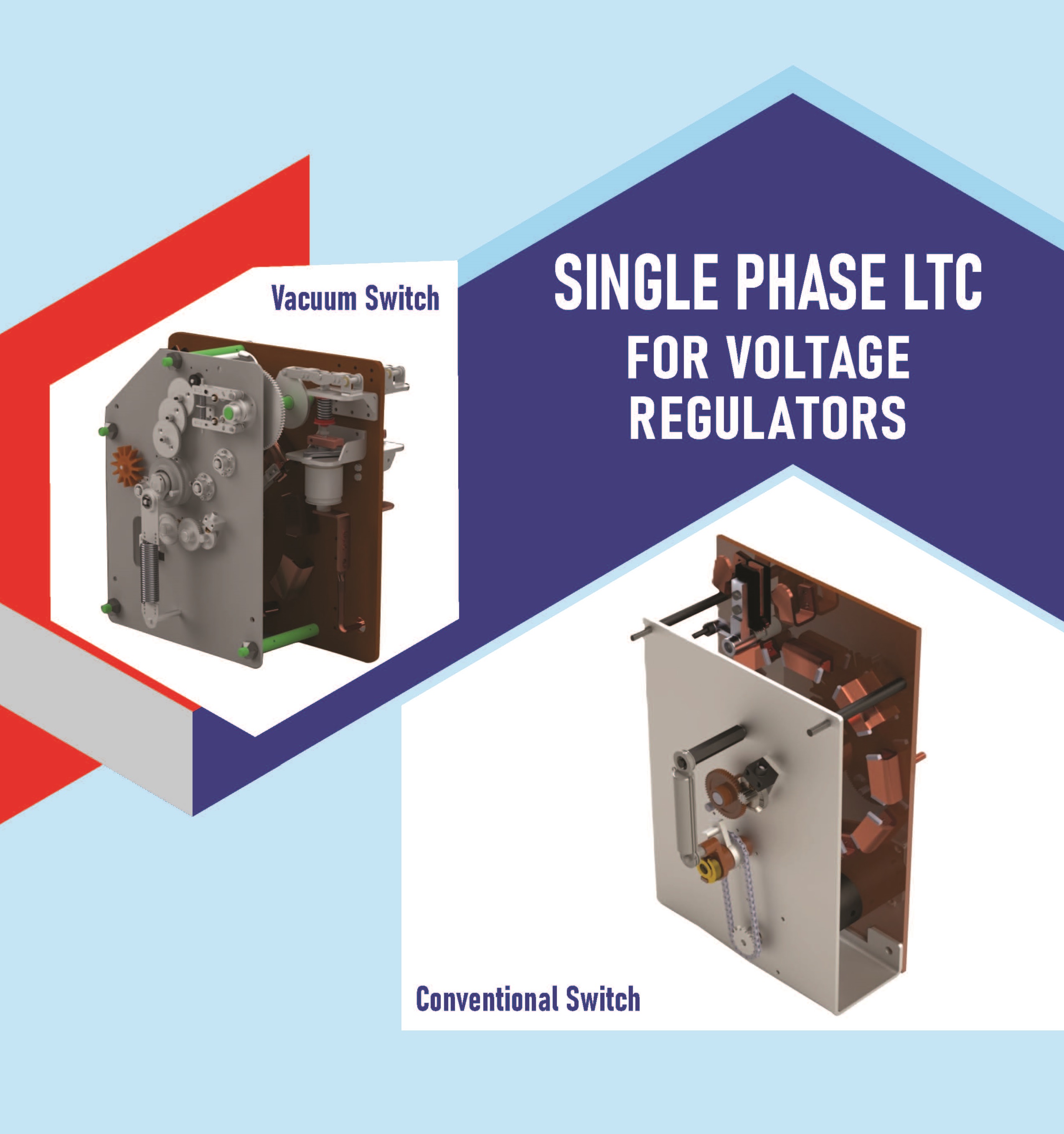

Manufacturing

State-of-the-art manufacturing facilities with quality assurance and precision engineering.

Maintenance & Service

Proactive maintenance and round-the-clock support services to minimize downtime.

About OEIPL

ONLOADGEARS EXPORTS INDIA PRIVATE LIMITED is managed by a team of professional managers with over 5 years of business experience and a customer base of more than 25 well reputed firms in India and abroad.

Employing 30 committed employees between 2 different locations with a built up area of more than 75,000 sq.ft. of manufacturing and office space.

Learn MoreWhy Choose Us

We stand out from the competition with our exceptional services and expertise

5+ Years Experience

Decades of industry expertise and knowledge

30+ Employees

Dedicated team of professionals

75,000 Sq.Ft. Space

Modern manufacturing facilities

Global Reach

Serving clients across the world